Whether its a broken part, low volumes or long lead times stressing your business objectives, we can help

We're an Australian business ready to solve your manufacturing headaches with the latest industrial 3D printing technology

Discover How Additive Manufacturing Can Save You Time & Money. Request an Obligation Free Consultation

We specialise in Business to Business Industrial Additive Manufacturing

What We Do

Rapid Turnaround Times

Need parts quickly? We can get you up and running quickly with a tailored manufacturing process and delivery schedule that suits you

Enhanced Quality Control

Our stringent quality control measures ensure your parts meet the challenges of its application when in use.

Customised Solutions

As an Australian business with a team of qualified engineers, we offer tailored solutions, adapting designs to specific local requirements or standards.

Supply Chain Resilience

Local services eliminate international shipping delays, enabling faster prototyping and production cycles.

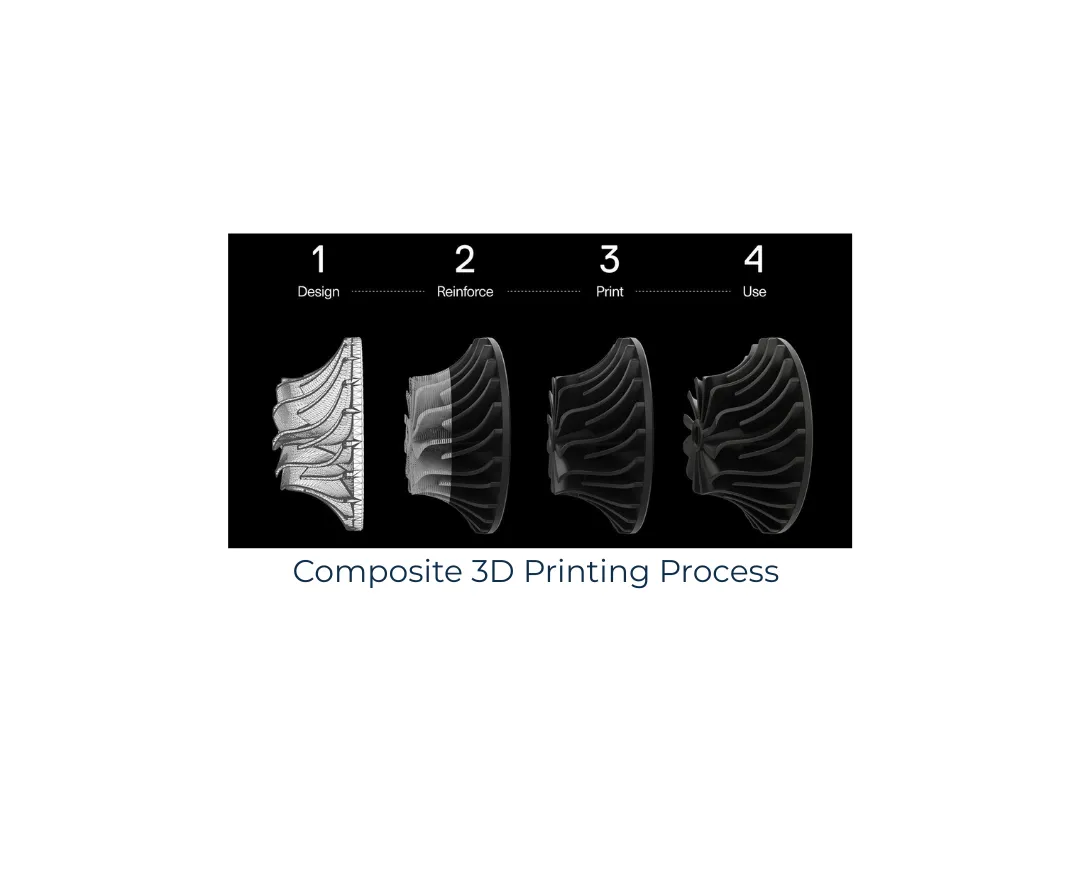

Design for Additive Expertise

Parts are engineered specifically for 3D printing to reduce weight, consolidate assemblies and improve performance.

Sustainable Manufacturing

On-demand, low-volume production runs with local shipping reduces material usage & emissions, supporting environmental sustainability goals.

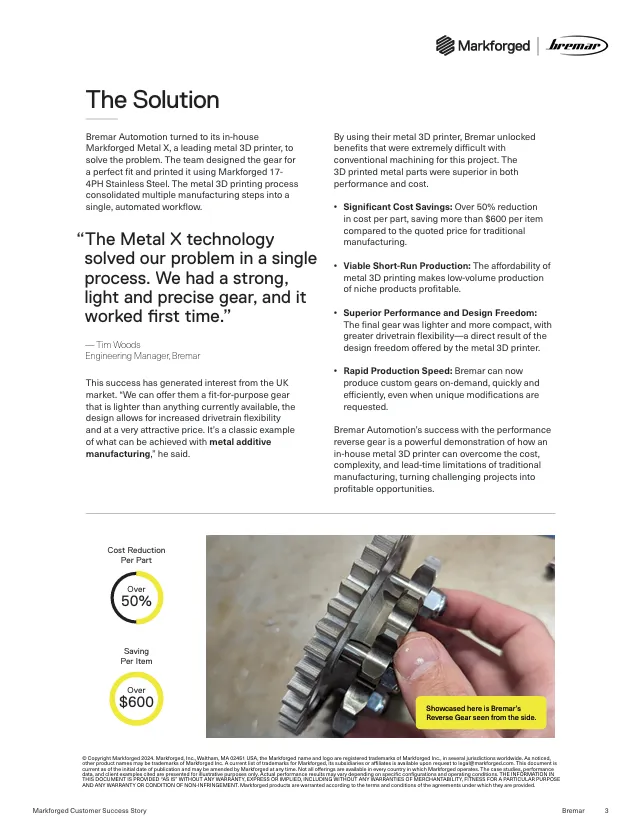

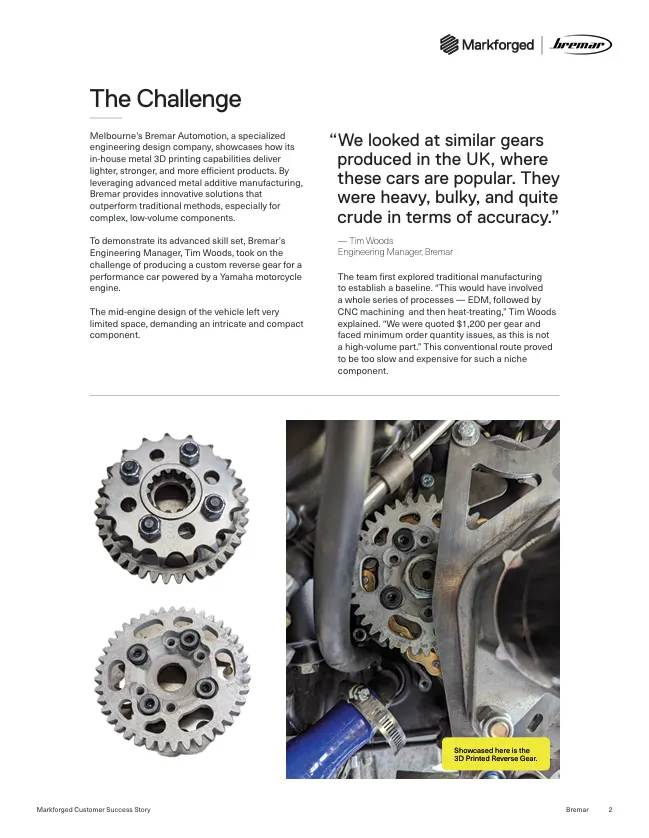

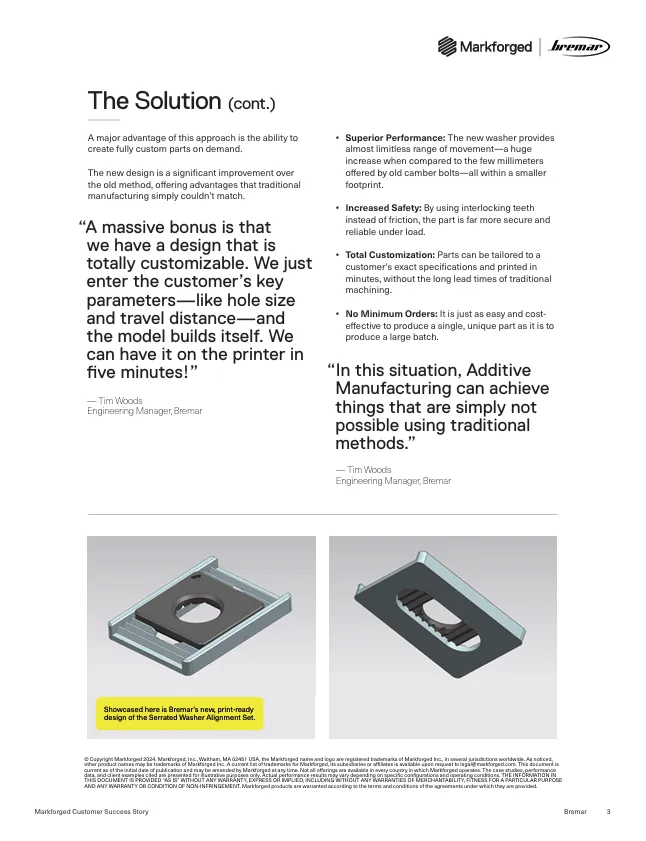

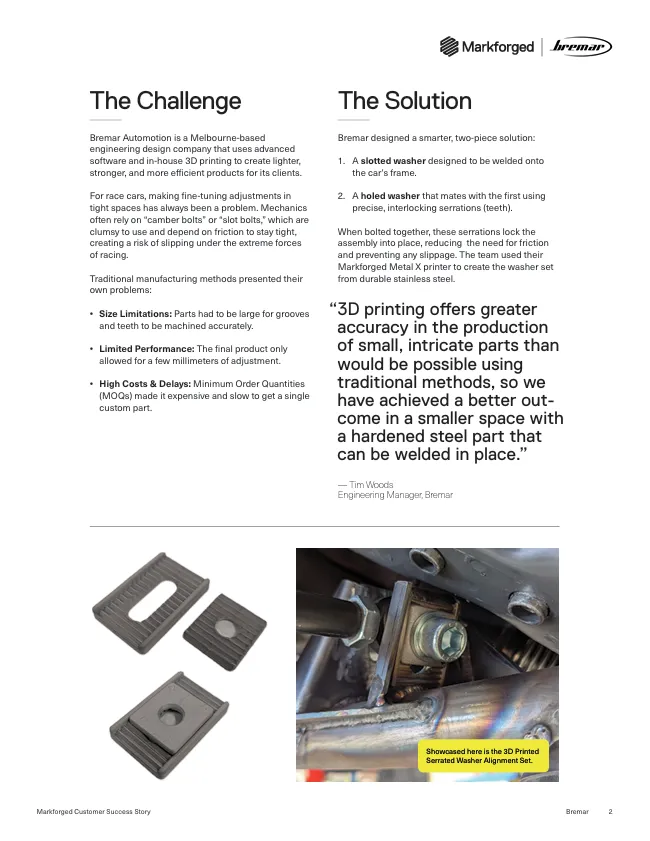

Additive Manufacturing Case Studies

STILL NOT SURE?

Frequently Asked Questions

We understand you may have some questions before speaking with us

What kind of customers do you work with?

Our clients have an industrial application for the parts we print that require high strength, light weight or UV/Fire resistant qualities.

We work with engineering-led teams that need high-performance parts — in polymer or metal — delivered with the strength, accuracy, and consistency of production hardware.

Typical customers include:

- Manufacturers needing durable replacement parts without committing to new tooling.

- Businesses under time pressure who need quick turnaround and production-ready quality.

- Organisations looking for a true end-to-end partner for design optimisation, material selection, simulation & build.

- Motorsport and race teams chasing strong, lightweight components

- Engineers tackling complex geometry that’s difficult or impossible to machine, cast, or mould.

In short, we work with customers who need more than a print bureau. They want engineered polymer and metal parts that carry load, shed weight, survive harsh environments, and solve real manufacturing constraints.

Is my design and data kept confidential?

Absolutely. We take confidentiality seriously and are happy to sign NDAs if required. Your design files and printed parts remain your intellectual property.

Can you help with design or engineering support?

Yes. We offer design-for-additive-manufacturing (DfAM) advice, strength optimisation, and fiber routing consultation to help you get the most out of your printed part.

What file formats do you accept for printing?

We accept STL, STEP, IGES, and other standard 3D CAD file formats. Our team can assist in converting or preparing your files if needed.

What is your typical turnaround time?

Depending on complexity and queue, most low volume orders are fulfilled within 2–5 business days for composite parts, while metal parts are between 5-7 days. Expedited services are available upon request.

How strong are the parts you produce?

Parts printed with continuous carbon fiber can rival or exceed aluminum strength in many applications. They're suitable for mechanical and structural use, not just prototyping.

What materials can I choose from?

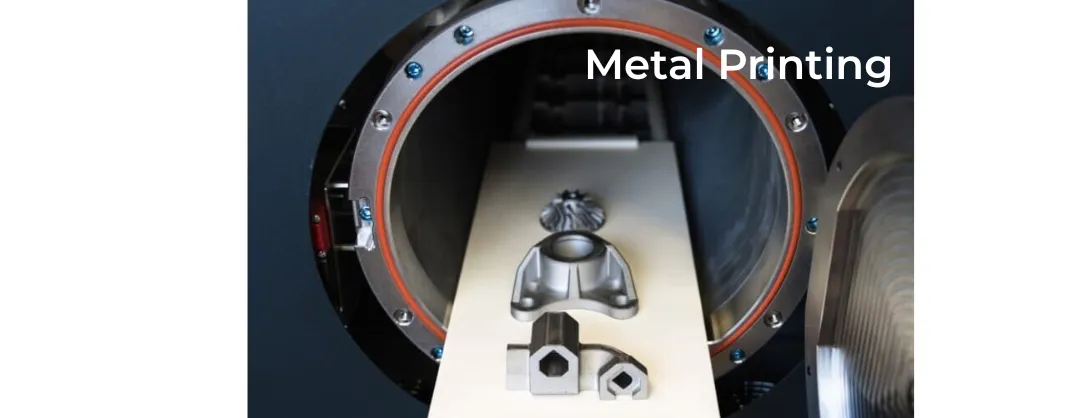

We offer a range of composite materials and continuous fibre reinforcement including but not limited to, Onyx, ULTEM 9085, Vega, TPU, Nylon , carbon fibre, fiberglass, Kevlar, HSHT fiberglass. For our Metal X system we offer stainless steel (17-4PH), tool steel (D2, H13), inconel 625 and copper

What are the size limits for your printed parts?

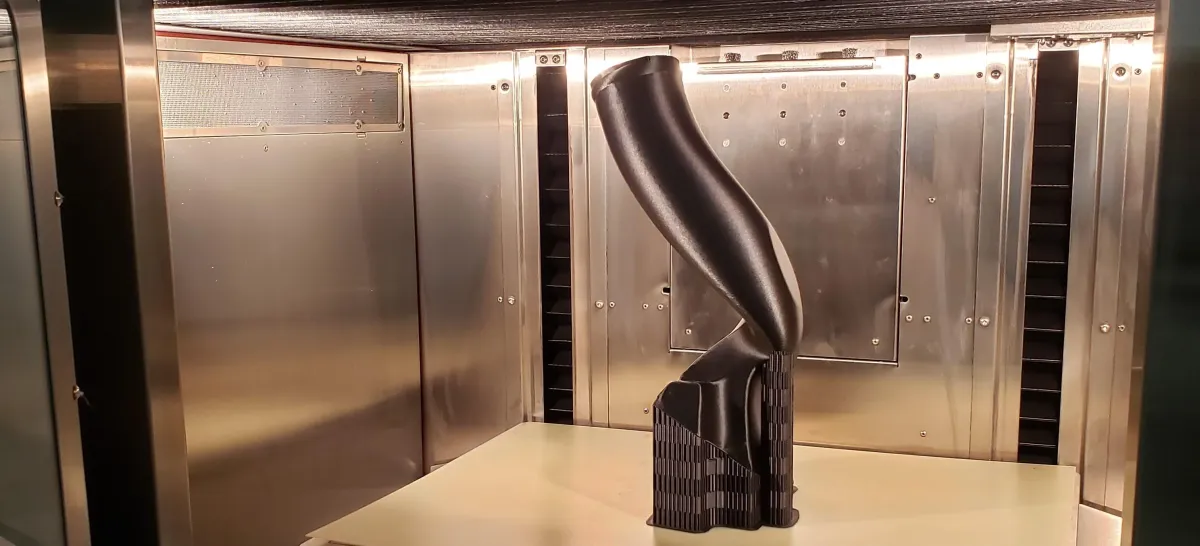

Our build volumes vary by printer model. The largest parts we can produce in one piece are approximately 525 x 400 x 400 mm (FX20 system), but we can split and assemble larger parts.

What industries do you serve with Markforged printing?

We support clients across aerospace, automotive, manufacturing, medical, defense, and product design, offering high-strength parts for prototyping, tooling, fixtures, and low-volume production.

What makes Markforged 3D printing different from other 3D printing technologies?

Markforged printers use industrial-grade materials like Onyx and continuous carbon fiber, producing parts with strength comparable to aluminum. We offer functional prototypes and end-use parts with superior surface finish and strength.

TESTIMONIALS

What others are saying

Rally Technic

We could not be happier with their professionalism and technical knowledge. We highly recommend Bremar’s services.

Darryn Kelbrick, Principal Engineer - RALLY Technic

Rob Black (Aust.) Pty Ltd

We have found their attention to detail, consideration of ‘how to manufacture’ and problem solving very good and can highly recommend their services.

Ross Black,

RK Findlay Pty Ltd Consulting Engineers

We have used Bremar for many years and I would highly recommend using their services.

Craig Findlay

Does this sound familiar?

You only need a few parts printed and are prevented by minimum order quantities.

You're concerned about sharing your design and the risk of intellectual property theft or misuse.

You're tired of searching for industrial 3D printers that can offer fast turnarounds on high quality, high strength parts, ready for real world usage.

Don't worry, we can help!

About us

Nice to meet you

Bremar Additive is passionate about providing solutions to your problems. Our fleet of industrial 3D printers produce high quality, high strength end use parts capable of servicing your needs straight off the line.

We're more than a print bureau. Our experienced engineers provide end-to-end solutions:

- Reverse engineering obsolete parts to get you back online fast.

- Optimising existing designs for Additive Manufacturing.

- Creating entirely new products with AM at the core.

We're Victoria's Markforged Centre of Excellence for Additive Manufacturing servicing small & large production runs across a range of industries

Manufacturing businesses have experienced an 80% reduction in time spent and a 30% reduction in tooling costs using Additive Manufacturing for customised tools and fixtures.

We are registered engineers that can test your part for strength, durability and compliance with relevant standards

terms & conditions

Acceptance of Terms

By requesting a quote or submitting an order for additive manufacturing services, the Client agrees to abide by these Terms C Conditions. These terms apply to all additive manufacturing projects performed by Bremar Additive.

Scope of Services

Bremar Additive provides additive manufacturing services based on CAD files supplied by the Client. Bremar Additive will not modify or alter designs provided by the Client unless expressly agreed upon in writing. Such services may incur additional charges which will form part of the quotation and agreed pricing

Client Supplied CAD Files

The Client is responsible for ensuring that all files submitted are correct, complete, and suitable for additive manufacturing. Bremar Additive will not be held liable for errors resulting from design flaws, inaccuracies, or omissions in the Client's CAD files. The Client also warrants that they own the files being provided, and/or the supply of files to Bremar Additive does not infringe on third party rights or ownership

Samples s Approval

Upon request, Bremar Additive will provide a sample of the part(s) for the Client's review before full production. Cost of sample parts is at Bremar Additive's discretion. It is the Client’s responsibility to approve the sample and confirm it meets their requirements. Any additional design adjustments after sample approval may incur additional charges. By approving the sample, the Client accepts responsibility for the part’s design and application suitability, and the subsequent cost for any rework, redesign, reprints, or other modifications will be borne by the Client

Material Selection

Bremar Additive will use materials specified by the Client, if available. Bremar Additive will advise on suitable materials where required but is not responsible for any material-related issues, such as strength, wear, durability, or suitability for the Client’s specific application unless explicitly stated and agreed to in writing. If material selection is in question, sample parts should be requested for client testing and approval

Part Post Processing

Parts will be provided "as is" from the printing process. Post processing including but notlimited to: removal of printing supports, joining of separate parts, additional inserts / hardware / etc, surface smoothing / sanding / coating will be the client's responsibility unless otherwise agreed as part of the provided quotation

Liability Limitation

Bremar Additive’s liability for any claim arising from an additively manufactured part, whether due to material quality, accuracy, or design, is strictly limited to the cost of the part produced. Bremar Additive assumes no liability for damages arising from the part’s failure, whether in regular or abnormal use, and disclaims all implied warranties, including fitness for a particular purpose.

Intellectual Property

The Client retains full ownership of all designs, drawings, and intellectual property provided to Bremar Additive. Bremar Additive agrees not to use or reproduce the Client’s designs for any purpose other than fulfilling the order without express written permission from the Client.

Payment Terms

Full payment is required upon approval of the quote, unless otherwise agreed. Production will not commence until payment is received. Any outstanding balance must be cleared before delivery or shipment.

Confidentiality

Bremar Additive will treat all Client information, files, and designs as confidential. Bremar Additive will not disclose this information to third parties without the Client's written consent, except as required by law.

Governing Law

These Terms C Conditions are governed by the laws of Victoria Australia, and any disputes arising from these services will be resolved within this jurisdiction.

Privacy policy

This Privacy Policy explains how Bremar Additive collects, uses and protects personal information provided through our website, landing pages and online forms.

Information We Collect

We may collect personal information such as your name, email address, phone number, business details and any other information you submit when requesting quotes or contacting us.

If you make a purchase, we may also collect payment information processed securely through our payment partners.

Our website may use cookies and analytics tools to collect non-identifying data such as browser type, device information and pages viewed.

How We Use Personal Information

We use the information you provide to respond to enquiries, supply quotes, process orders and deliver our services.

We may use your information to improve our website, customer experience and service offerings.

If you opt in, we may use your contact details for marketing updates, newsletters or promotional materials related to Bremar Additive.

Sharing Your Information

We may share necessary information with trusted third parties who help us operate our business, including shipping partners, payment processors and technology providers.

These third parties are required to protect your information and use it only for the services they provide to us.

We do not sell or rent your personal information to any other parties.

Data Security

We take reasonable steps to protect your information through secure systems, encryption where appropriate and restricted internal access.

While we follow industry best practices, no method of transmission or storage is completely secure. We continuously review our systems to maintain a high level of protection.

Your Rights

You can request access to the personal information we hold about you.

You can ask us to correct inaccurate information or request deletion of your data, subject to any legal requirements to retain certain records.

You can opt out of marketing communications at any time.

Contact Us

If you have questions about this Privacy Policy or wish to make a data request, you can contact us at: [email protected]